To safely restore vintage electronics, always wear personal protective equipment like gloves and goggles to guard against toxic materials and sharp edges. Guarantee the device is unplugged and verify no voltage remains before working. Use proper tools and keep your workspace organized to prevent accidents. Recognize hazardous components such as old capacitors and leaded solder, handling and disposing of them safely. Carefully test and document each step—continue with these safety practices to protect yourself and ensure a smooth restoration process.

Key Takeaways

- Always disconnect power and verify the absence of voltage before beginning restoration work.

- Wear appropriate personal protective equipment, including gloves, goggles, and masks, to handle hazardous materials safely.

- Use proper tools, organized workspace, and follow circuit diagrams for precise and safe repairs.

- Properly dispose of old components at certified e-waste centers, avoiding environmental contamination.

- Maintain detailed documentation and label parts to ensure safe handling and accurate reassembly.

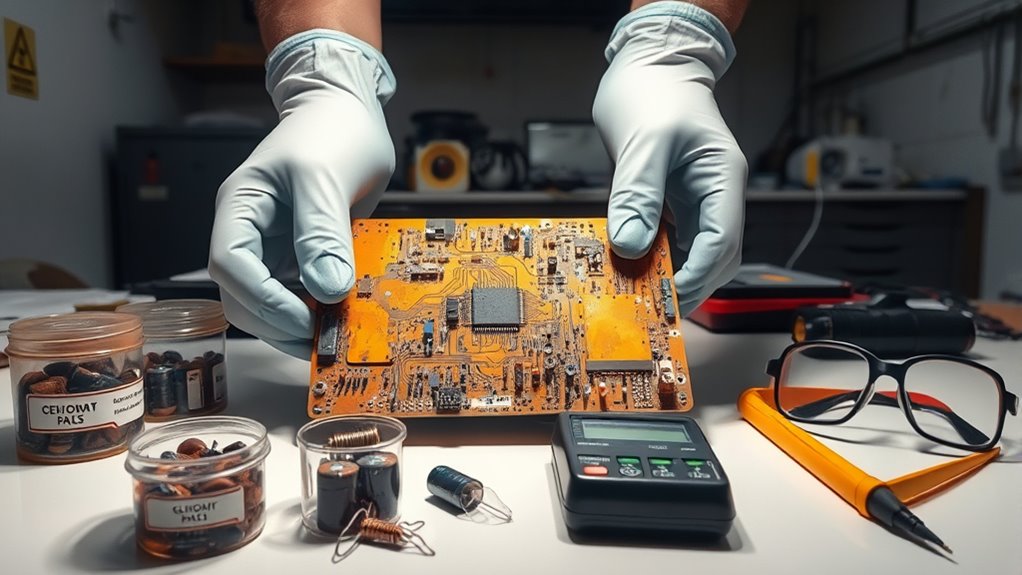

Wear Appropriate Personal Protective Equipment

Have you ever considered how vital it is to wear the right personal protective equipment (PPE) when restoring vintage electronics? Vintage devices often contain liquid hazards like old capacitors or corrosion that can leak hazardous fluids. These liquids can cause skin irritation or damage if spilled or splashed. Additionally, working with vintage electronics poses a risk of electrical shock, especially if insulation has deteriorated over time. Wearing insulated gloves, safety goggles, and a protective apron helps shield you from liquid hazards and reduces the chance of electrical shock. PPE acts as a fundamental barrier, keeping dangerous substances and accidental shocks away from your skin and eyes. Prioritizing proper PPE ensures you can focus on your restoration work safely and effectively. Proper vetted safety gear is essential for working with delicate and potentially hazardous vintage components. Being aware of vintage electronic hazards can further enhance your safety precautions.

Disconnect Power Sources and Verify Absence of Voltage

Before working on vintage electronics, you need to disconnect all power sources using proper equipment. Always double-check that the device is completely powered off with a reliable voltage tester. This step guarantees your safety and prevents accidental shocks during restoration. Additionally, verifying indoor air quality can help ensure a healthier environment when working in enclosed spaces. Regularly inspecting your workspace for hazardous materials such as old batteries or chemicals is also essential to maintain safety standards. Incorporating proper safety protocols can further minimize risks during your restoration process. Familiarity with headphone jacks and their correct handling can prevent damage to delicate components and ensure proper functioning post-repair.

Use Proper Equipment

Ensuring safety during vintage electronics restoration begins with disconnecting power sources and verifying that no voltage remains. Using proper equipment is vital to avoid accidents and damage. Always employ a multimeter to accurately check for residual voltage, and ensure your tools are insulated and rated for the voltages involved. Proper grounding techniques help prevent static discharge and electrical shock. Additionally, clearly label components to track connections and prevent mistakes during reassembly. Being aware of AI vulnerabilities in safety systems can help in designing more reliable protective measures. Incorporating safety protocols based on current standards further enhances protection during restoration. Familiarity with circuit diagrams can also improve safety by providing a clear understanding of the electronics involved.

Confirm Power Is Off

To safely work on vintage electronics, you need to confirm that all power sources are disconnected and that no voltage remains in the device. Start by unplugging the power cords and disconnecting any external power supplies. Use proper grounding techniques to prevent static buildup and accidental shocks. Next, verify electrical isolation by testing each component with a multimeter set to voltage detection. Make sure there’s no residual charge in capacitors or other stored energy sources. Always double-check your work before proceeding further. Proper grounding techniques and electrical isolation are vital for your safety, preventing accidental shocks or damage to the device. Confirming power is off ensures a safe environment, protecting both you and the vintage electronics during restoration. Additionally, understanding the importance of high contrast ratios can help in assessing the safety and performance of display components within vintage electronics. It is also helpful to remain aware of the potential dangers of residual charge to ensure thorough safety precautions are taken, especially considering the diverse materials and components involved in vintage electronics restoration. Incorporating knowledge about voltage regulation can further enhance safety measures by ensuring voltage levels are properly controlled during the repair process.

Use Proper Tools and Workspaces

Using the right tools and setting up an organized workspace are essential steps in restoring vintage electronics effectively. Proper tools ensure you can work precisely and safely, while a clean workspace minimizes mistakes and damage. Keep your workspace organized by designating specific areas for components, tools, and manuals. Use fine-tipped screwdrivers, multimeters, and soldering irons suited for delicate work. Label components clearly to prevent confusion during reassembly, aiding component labeling and tracking. An uncluttered area improves workflow and reduces the risk of losing small parts. Consider using anti-static mats and proper lighting to enhance safety and accuracy. Remember, a well-structured workspace empowers you to work efficiently, reduces errors, and preserves the integrity of vintage electronics throughout the restoration process. Incorporating industry best practices can further increase your success rate and ensure long-term preservation. Additionally, implementing proper safety protocols ensures your safety during restoration activities. Maintaining an awareness of static electricity hazards is also crucial when handling sensitive electronic components.

Understand and Identify Hazardous Components

Understanding and identifying hazardous components is essential for your safety and the integrity of the restoration process. Vintage electronics often contain hazardous chemicals like old capacitors with PCB-based dielectric fluids, which can be toxic if disturbed. You should also watch out for electrical hazards, such as exposed wiring, faulty insulation, or damaged components that could cause shocks. Carefully examine circuit boards and components for signs of corrosion, leaking capacitors, or discoloration, which may indicate danger. Always assume that certain parts could be hazardous until verified. Wearing protective gear, like gloves and eye protection, is vital when inspecting or handling these components. Recognizing these hazards early helps prevent accidents and maintains a safe working environment during your restoration project. Additionally, understanding hackathons can provide opportunities to learn new problem-solving techniques and safety protocols from experienced enthusiasts and professionals. Staying informed about emerging safety standards can also help you adopt best practices and ensure compliance during your restoration work. Being aware of cryptocurrency market trends can also inspire you to stay informed about evolving risks and opportunities in digital assets. Moreover, consulting vintage electronics safety guidelines can offer specific procedures tailored to handling older components safely.

Handle and Dispose of Old Components Safely

When handling old electronic components, you need to wear protective gear to avoid harmful exposure. Always follow proper disposal methods to prevent environmental contamination, especially with toxic materials. By taking these precautions, you keep yourself safe and make certain of responsible recycling of vintage parts. Additionally, understanding the toxicity of certain materials used in vintage electronics can help you take more targeted safety measures.

Wear Protective Gear

Handling and disposing of old electronic components safely is crucial because many vintage parts contain hazardous materials like lead, mercury, or cadmium. When working with vintage soldering or inspecting antique insulation, always wear protective gear to prevent exposure. Use sturdy gloves to avoid contact with toxic residues or sharp edges, and safety goggles to shield your eyes from splashes or debris. A dust mask is necessary when cleaning or sanding old components, which may release harmful particles. Additionally, consider wearing a long-sleeved shirt and respiratory protection if you’re dealing with deteriorated insulation or solder joints. Proper protective gear not only safeguards your health but also ensures a safer restoration process, especially when handling components that may contain hazardous substances or fragile vintage materials.

Proper Disposal Methods

Proper disposal of old electronic components is essential to prevent environmental contamination and health risks. Many vintage parts contain chemical hazards like lead, mercury, or cadmium, which can leach into soil and water if not disposed of correctly. You should never throw these items in regular trash, as they contribute to environmental impact. Instead, take your components to certified e-waste recycling centers that handle hazardous materials safely. Follow local regulations for disposal; some areas have specific collection events or drop-off sites for electronic waste. Proper disposal not only protects the environment but also reduces the risk of exposure to toxic substances. Always wear protective gear when handling old electronics, and stay informed about safe disposal practices to ensure you’re minimizing harm.

Avoid Toxic Materials

Ever wonder how to keep yourself safe while working with vintage electronics? Handling old components can expose you to chemical hazards and lead exposure, so it’s essential to be cautious. Always wear gloves and work in a well-ventilated area to minimize risks. Be mindful when inspecting or removing parts that may contain toxic materials. Proper disposal is vital—don’t toss vintage components in regular trash. Instead, follow these guidelines:

- Use designated hazardous waste containers for old capacitors and circuit boards

- Avoid burning or melting components, which releases toxic fumes

- Consult local regulations for disposal of leaded solder and other toxic materials

Taking these steps protects you from chemical hazards and reduces environmental impact. Your safety should always come first when restoring vintage electronics.

Test and Diagnose With Care and Precision

When testing and diagnosing vintage electronics, taking your time and working carefully can prevent costly mistakes. Follow proper testing procedures to ensure accurate results and avoid damaging delicate components. Begin with thorough component identification to understand what parts are present and their functions. Use a multimeter to check resistors, capacitors, and continuity, noting any irregularities. Pay close attention to wiring and connections, as corrosion or previous repairs may cause confusion. Document your findings carefully, so you can track issues and avoid repeating mistakes. Remember, patience is key—rushing can lead to overlooked problems or damage. By approaching testing with precision and care, you set a solid foundation for a safe and successful restoration.

Maintain Documentation and Keep Safety First

Maintaining detailed documentation throughout your restoration process is essential to track progress, identify recurring issues, and guarantee consistency. Proper labeling practices ensure components are easily identified, reducing errors during reassembly. Keep a clear record of wiring diagrams, part replacements, and testing results to streamline troubleshooting. Storage considerations also play a crucial role; organize parts and tools systematically to prevent damage and loss. Using labeled containers or bins helps keep small components accessible and protected. Additionally, document safety procedures you follow to maintain a safe working environment. By prioritizing thorough documentation, labeling practices, and proper storage, you minimize risks and enhance the quality of your vintage electronics restoration. Staying organized and safety-conscious ensures a smoother, more successful restoration process.

Frequently Asked Questions

How Can I Identify Hidden or Internal Hazards in Vintage Electronics?

You can identify hidden hazards in vintage electronics by closely inspecting the circuit board for corrosion, which indicates moisture damage and potential short circuits. Check for bulging or leaking capacitors, signs of internal capacitor failure that could cause electrical issues or fires. Use a magnifying glass and a multimeter to detect unseen corrosion or faulty components. Always make certain the device is unplugged before inspecting to avoid shock hazards.

What Are the Best Methods for Cleaning Vintage Electronic Components Safely?

To clean vintage electronic components safely, use gentle cleaning techniques like soft brushes and lint-free cloths. For stubborn dirt, apply isopropyl alcohol (at least 90%) in a well-ventilated area, ensuring chemical safety by avoiding inhalation and skin contact. Never use harsh chemicals or abrasive tools that could damage parts. Always let components dry thoroughly before powering up, and wear protective gloves to prevent contamination.

Are There Specific Storage Conditions to Preserve Vintage Electronic Parts?

To preserve vintage electronic parts, you should store them in a controlled environment with stable temperature and humidity levels. Keep components in airtight containers to prevent corrosion, and guarantee proper labeling for easy identification. Avoid extreme temperatures and direct sunlight, which can damage delicate parts. Regularly check storage conditions and maintain proper labeling to prevent mix-ups, ensuring your vintage electronics stay in good condition for years to come.

How Do I Prevent Static Damage During Restoration Processes?

Think of static as a silent thief stealing your vintage parts’ life. To prevent static damage, always practice grounding techniques—touch a grounded metal object before handling components. Use anti-static bags to store sensitive parts, creating a shield against static buildup. When working on restoration, wear an anti-static wrist strap connected to ground. These simple steps act as your shield, ensuring your restoration process remains safe and your vintage electronics stay intact.

What Are the Legal Considerations for Restoring and Disposing of Vintage Electronics?

You need to guarantee legal compliance by understanding disposal regulations for vintage electronics, especially those containing hazardous materials like lead or mercury. Check local, state, and federal laws before restoring or disposing of these items. Properly document your actions, and consider certified disposal services for hazardous waste. Staying informed about regulations helps you avoid fines and environmental harm, ensuring your restoration project remains legal and responsible.

Conclusion

Restoring vintage electronics is like tending a delicate garden—you must handle each plant with care and patience. I once rushed into a project and ended up damaging a rare radio; now I know that following safety steps is essential. By wearing proper gear, working methodically, and respecting hazardous parts, you protect yourself and your treasure. Remember, safety isn’t just a step—it’s the foundation that keeps your passion alive and flourishing.