Vinyl records produce sound through grooves etched during manufacturing that encode audio signals via tiny variations in width and depth. As the record spins, the stylus traces these grooves, converting physical vibrations into electrical signals through the cartridge. These signals are then amplified and played back through speakers. The quality of sound depends on precise groove cutting, stylus contact, and playback equipment. Keep exploring how every step contributes to the warm, rich sound you enjoy.

Key Takeaways

- Vinyl records encode sound through physical grooves with variations that represent audio waveforms.

- A stylus traces these grooves, converting physical vibrations into electrical signals for playback.

- Groove modulation encodes amplitude and frequency, translating into volume, pitch, and stereo sound.

- Manufacturing quality and material properties influence the accuracy of groove imprinting and sound clarity.

- Proper setup and maintenance of turntables, tonearms, and stylus ensure faithful sound reproduction.

The Origin of the Grooves on Vinyl Records

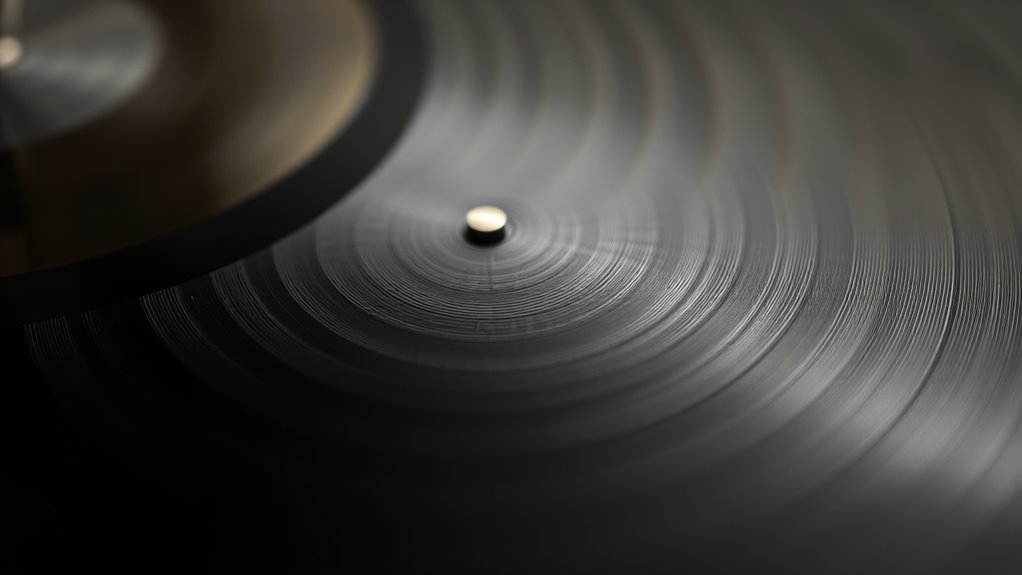

Have you ever wondered how the grooves on vinyl records came to be? The intricate record groove patterns are the result of early vinyl pressing techniques that transformed sound into physical form. During manufacturing, audio signals are etched onto the surface through a process called cutting, where a stylus carves tiny, spiral grooves into a master disc. These grooves encode the sound vibrations in a specific pattern, with variations in width and depth. The precision of vinyl pressing techniques guarantees that each record carries an accurate physical imprint of the original recording. Over time, these patterns became more refined, allowing for higher fidelity sound reproduction. The development of record manufacturing methods played a crucial role in the evolution of vinyl sound quality. Proper calibration and pressing techniques ensure that each record maintains fidelity to the original audio. Additionally, advancements in material properties of the vinyl contribute to durability and sound clarity. Modern quality control measures help detect imperfections that could affect sound fidelity. Understanding the origin of these grooves reveals how sound transformed into a tangible medium, ready to be played back through a turntable. Moreover, ongoing innovations in vinyl materials continue to enhance audio fidelity and longevity.

How Sound Waves Are Encoded in the Groove

The grooves on a vinyl record don’t just look intricate; they serve as a physical code for sound waves. During recording, sound wave encoding happens through groove modulation, where variations in the groove’s shape represent different audio signals. As the needle traces the groove, it detects these modulations and converts them back into sound. The depth, width, and lateral shifts of the groove encode the amplitude and frequency of the original audio. This process guarantees that each nuance of the sound is preserved physically within the groove’s structure. Understanding this encoding helps explain why vinyl records produce such rich, warm sound. Sound encoding techniques are essential for maintaining fidelity in analog formats. – The groove’s shape changes encode volume and pitch. – Lateral shifts correspond to stereo sound. – Precise groove modulation captures every detail of the original recording. – The physical encoding process is a key aspect of sound preservation.

The Manufacturing Process of Vinyl Records

You start by selecting the right material, usually vinyl, which affects sound quality and durability. Next, skilled technicians create stampers from the original recording to guarantee accurate reproduction. Finally, these stampers are used in molding machines to produce the actual records, shaping the grooves that encode the music. Incorporating technological innovation in the manufacturing process can further enhance sound fidelity and production efficiency.

Record Material Selection

Selecting the right material is crucial in the manufacturing process of vinyl records, as it directly impacts sound quality and durability. The choice of record material determines how well the vinyl can reproduce audio and withstand repeated playbacks. Typically, vinyl composition includes polyvinyl chloride (PVC), which provides flexibility and strength. The precise formulation affects the record’s ability to capture fine details and reduce noise. High-quality vinyl composition results in clearer sound and longer-lasting records. Additionally, the formulation of the vinyl can influence sound fidelity and the overall listening experience. Advances in material formulation and additive technologies continue to enhance the performance of vinyl records, ensuring better sound reproduction and durability over time. Understanding material properties is essential for manufacturers to optimize records for both sound quality and longevity. Proper record pressing techniques also play a significant role in maintaining the integrity of the audio during production, and ongoing research in manufacturing technology helps improve these processes further.

Stampers and Molding

Stampers and molding are central to the vinyl record manufacturing process, translating the audio master into a physical format. You start with a master disc, which is used to create a metal stamper through electroforming. This stamper acts as a mold, imprinting the grooves that carry sound information onto vinyl. During pressing, molten vinyl is pressed between two stampers, forming the record’s grooves. Proper stamper maintenance guarantees consistent quality, essential for vinyl preservation and maintaining your record collection’s integrity. As stampers wear over time, audio fidelity can decline, making it critical to produce high-quality copies. Understanding this process helps you appreciate the craftsmanship behind each vinyl, guaranteeing your collection remains valuable and sounds great for years to come. stamper maintenance is crucial for ensuring long-term quality and preventing defects in pressed records. Regular inspection and timely replacement of worn stampers enhance the fidelity and durability of the final product, emphasizing the importance of manufacturing precision in vinyl production. Maintaining high standards in stamper quality control ensures that each record meets the desired sound fidelity and durability, especially since electroforming is a delicate process that influences the final outcome.

The Role of the Turntable and Tonearm

The turntable’s mechanics are essential for preserving sound quality, ensuring the record spins smoothly and consistently. The tonearm’s design and movement directly affect how accurately the needle follows the grooves. Understanding these components helps you appreciate how they work together to produce clear, detailed sound. Additionally, advancements in automation technologies are increasingly used in audio equipment to optimize playback performance and maintenance. Proper calibration of the tonearm balance is crucial for minimizing wear on the record and stylus, further enhancing sound fidelity. Regular maintenance can also prevent issues that may degrade audio quality over time.

Turntable Mechanics

Ever wondered how a turntable translates grooves into sound? The turntable’s mechanics are crucial for accurate vinyl preservation, guaranteeing your records sound their best. When you place a record on the platter and start spinning, the stylus tracks the groove’s variations, converting physical undulations into electrical signals. The stability of the platter keeps vibrations minimal, maintaining sound clarity. Proper record cleaning prevents dust from disrupting playback, which can affect groove contact. The tonearm’s precise movement ensures the stylus stays in the groove’s center, avoiding distortion. Key aspects include:

- Maintaining a stable platter for consistent rotation

- Ensuring the stylus accurately tracks the grooves

- Proper record cleaning to prevent unwanted noise

These mechanics work together to produce clear, accurate sound while helping you with vinyl preservation.

Tonearm Dynamics

Understanding tonearm dynamics is essential for guaranteeing your turntable produces accurate sound. The tonearm guides the cartridge across the record’s surface, affecting how vibrations are transferred. Proper cartridge alignment minimizes distortion and maintains consistent tonearm movement. Variations in tonearm weight, balance, and friction influence sound quality. When you optimize tonearm dynamics, you reduce tracking errors and uneven wear. Carefully adjusting the tonearm’s pivot and counterweight ensures smooth motion and accurate tracking.

| Aspect | Impact |

|---|---|

| Tonearm weight | Affects tracking force and resonance |

| Cartridge alignment | Ensures proper contact with record grooves |

| Pivot friction | Influences tonearm stability and movement |

| Balance | Prevents distortion and wear |

| Tracking force | Critical for sound fidelity and record longevity |

Understanding the Stylus and Cartridge Mechanics

To accurately reproduce sound from a vinyl record, you need to grasp how the stylus and cartridge work together. The stylus, or needle, tracks the record’s grooves, converting physical vibrations into electrical signals via the cartridge. Proper stylus pressure ensures consistent contact without damaging the record or skipping. Cartridge alignment is vital for ideal tracking and sound quality; misalignment can cause distortion or uneven wear. When set correctly, it allows the stylus to follow the grooves precisely, preserving the record’s fidelity.

- Understanding how stylus pressure affects sound quality and record longevity

- The importance of proper cartridge alignment for accurate playback

- How the stylus and cartridge interact to transmit vibrations efficiently

Converting Physical Grooves Into Electrical Signals

When the stylus moves through the record’s grooves, it encounters tiny ridges and valleys that encode the music. As it traces these microscopic patterns, the stylus vibrates in response to the groove’s variations. These vibrations are transferred to the cartridge, which converts them into electrical signals through electromagnetic induction. Proper record cleaning guarantees dirt doesn’t interfere with this process, maintaining clear sound reproduction. Good record storage keeps the grooves pristine, preventing dust or warping that could distort signals. The cartridge’s needle captures the groove’s physical undulations, transforming them into tiny electrical currents. These signals then travel through the tonearm, ready for amplification. This delicate conversion process is what allows your vinyl to produce rich, authentic sound from physical grooves.

Amplification and Playback of the Signal

Once the stylus converts the grooves into tiny electrical signals, these signals need to be amplified to audible levels. This is where your amplifier comes into play, boosting the weak signals without sacrificing sound fidelity. A good amplifier preserves the dynamic range, ensuring loud and soft sounds are reproduced accurately. It also maintains the integrity of the original recording, allowing you to enjoy nuanced details. To optimize your listening experience, consider these points:

A quality amplifier ensures clear, dynamic, and faithful sound reproduction from your turntable.

- Use a high-quality preamp to prevent signal loss

- Match your amplifier’s power with your speakers for clarity

- Regularly check connections to avoid interference

Factors Affecting Sound Quality in Vinyl Playback

The quality of sound during vinyl playback depends on several interconnected factors that influence how accurately the stylus reproduces the original recording. Proper record storage is essential; storing your records upright in a cool, dry environment prevents warping and dust accumulation, which can distort sound. Regular vinyl cleaning removes dirt, fingerprints, and static that can cause pops, crackles, and tracking issues. Even slight debris can interfere with the stylus’s contact with the grooves, reducing fidelity. Additionally, the condition of the record surface directly impacts sound clarity. Maintaining your records through careful storage and routine cleaning guarantees a smoother playback experience, preserving the nuances and warmth that make vinyl sound so rich and authentic.

Comparing Analog and Digital Sound Reproduction

Have you ever wondered how analog and digital sound reproduction differ in delivering music? The main distinction lies in how each method captures and reproduces sound signals. Analog recordings, like vinyl, offer a natural, warm sound with high sound fidelity, preserving nuances that digital sometimes misses. Digital formats often use digital compression, which reduces file size but can slightly compromise sound fidelity. This process can strip away subtle details, making digital sound less rich than vinyl for some listeners.

Analog captures full, warm sound; digital compression may reduce richness and subtle details.

- Analog captures continuous sound waves, maintaining fullness and warmth.

- Digital relies on sampling and compression, affecting sound fidelity.

- Vinyl’s analog nature avoids digital compression, preserving original nuances.

Innovations and Future Trends in Vinyl Technology

Recent innovations in vinyl technology are revitalizing the classic format by enhancing sound quality and durability. Manufacturers now incorporate digital sampling techniques to improve fidelity, capturing more nuanced audio details. This blending of digital methods with analog records bridges the gap between vintage appeal and modern clarity. Additionally, wireless transmission technologies are emerging, allowing vinyl enthusiasts to stream music directly from their records to wireless speakers or devices, eliminating cumbersome cables. These advancements make vinyl more versatile and accessible, appealing to new generations of listeners. Future trends also include improved stylus designs and eco-friendly manufacturing processes. As technology continues evolving, you’ll see even more seamless integration of vinyl with digital ecosystems, ensuring the format remains relevant while respecting its rich analog heritage.

Frequently Asked Questions

Why Do Different Vinyl Presses Sound Slightly Different?

You notice different vinyl presses sound slightly different because pressing variations and mastering differences play a role. Variations in how the record is pressed, such as temperature and pressure, can affect the groove quality and overall sound. Additionally, mastering choices, like equalization and dynamic range, influence the final sound. These factors combine to give each pressing a unique character, making your listening experience distinct even with the same album.

How Does Temperature Affect Vinyl Record Sound Quality?

Think of your vinyl record as a delicate boat sailing on a calm lake. When temperature fluctuates, it’s like choppy waters disrupting its journey, affecting temperature stability and sound fidelity. Too hot or cold, and the vinyl warps, dulling the sound. To keep your music pristine, maintain a stable environment, ensuring the record’s voyage remains smooth and the sound stays clear and true.

Can Vinyl Records Be Damaged by Improper Storage?

Yes, vinyl records can be damaged by improper storage. You should follow handling precautions by always holding records by the edges and avoiding touching the surface. Storage best practices include keeping records upright, in a cool, dry place away from direct sunlight and temperature fluctuations. Use protective sleeves and avoid stacking records horizontally, which can cause warping or scratches. Proper storage preserves sound quality and prolongs your records’ lifespan.

What Materials Are Used in High-Fidelity Vinyl Production?

Think of high-fidelity vinyl as a finely crafted symphony, where material composition and manufacturing techniques play a crucial role. You’ll find that high-quality records are made from virgin PVC, often blended with stabilizers and lubricants to enhance durability and sound clarity. Precision molding and meticulous quality control in manufacturing techniques ensure your record’s surface is smooth, capturing every nuance of your favorite music without distortion, making your listening experience truly exceptional.

How Do Remastered Records Differ From Original Pressings?

Remastered records differ from original pressings mainly in audio fidelity, as they undergo enhanced mastering techniques that improve sound clarity, balance, and detail. You’ll notice a cleaner, more dynamic audio experience, often with reduced surface noise. These updates aim to bring the recording closer to its intended sound, giving you a richer listening experience. Remasters preserve the essence of the original but leverage modern technology for superior sound quality.

Conclusion

Now that you know how vinyl records produce sound, it’s clear they offer a unique listening experience that digital can’t quite match. By understanding the intricate process behind each groove and turntable setup, you realize it’s not just playing a record — it’s an art form. Remember, it’s often said that the proof is in the pudding; in this case, the rich, warm sound of vinyl speaks for itself, making it worth the effort.